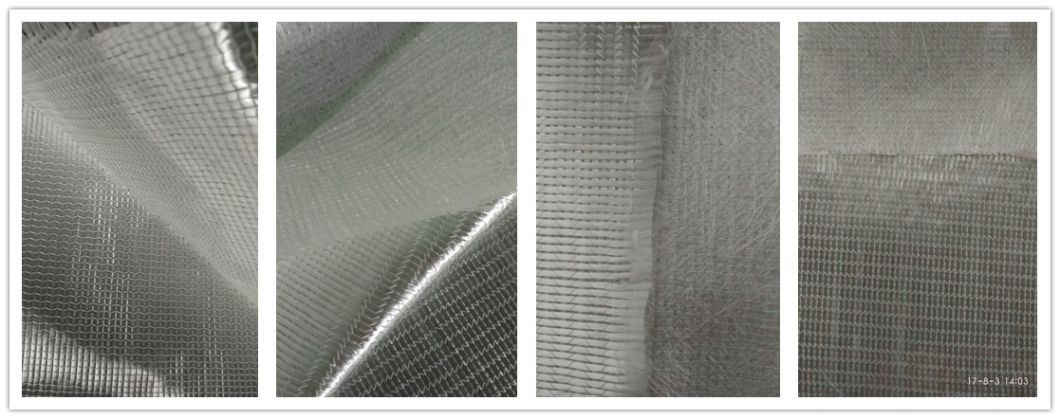

Fiberglass sanwidh mat is made with synthetic mat and chopped strand stitched together mechanically.

Fiberglass sanwidh mat is made with synthetic mat and chopped strand stitched together mechanically.Example :2 layers of 300gsm chopped strand mat with 180g/m2 or 250g/m2 PP core.

it is used for all the closed mold process needs and helps improve productivity and quality.

It is ideal for RTM and RTM light process.

Applications/Markets: Marine, Transportation, Industrial Goods, Windmill.

The application: Bus roofing, wind blade, boat, truck bodies and so on.

Properties:

No binder,no warp and weft direction corssing,no ruffled.

No displacement deformation.Good resistance to erosion,fast wet out.

Fast resin transfer speed,good manufacturability,good workability.

Good physical and chemical properties,and easy design to solution.

Technical Data:

Chopped core mat

| Code | Weight (g/m2) | Chopped layer (g/m2) | Core layer (g/m2) | Moisture content | Wet speed (≤S) |

| ES300/180/300 | 780 | 300/300 | 180 | ≤0.2 | ≤60 |

| ES450/180/450 | 1080 | 450/450 | 180 | ≤0.2 | ≤60 |

| ES600/180/600 | 1380 | 600/600 | 180 | ≤0.2 | ≤60 |

| ES750/180/750 | 1680 | 750/750 | 180 | ≤0.2 | ≤60 |

| ES300/250/300 | 850 | 300/300 | 250 | ≤0.2 | ≤60 |

| ES450/250/450 | 1150 | 450/450 | 250 | ≤0.2 | ≤60 |

| ES600/250/600 | 1450 | 600/600 | 250 | ≤0.2 | ≤60 |

| ES750/250/750 | 1750 | 750/750 | 250 | ≤0.2 | ≤60 |

Multiaxial core mat

| Code | Weight (g/m2) | Biaxial layer (g/m2) | Core layer (g/m2) | Chop layer (g/m2) | Moisture content | Wet speed (≤S) |

| EWF600/180/150 | 930 | 600 | 180 | 150 | ≤0.2 | ≤60 |

| EWF600/180/300 | 1080 | 600 | 180 | 300 | ≤0.2 | ≤60 |

| EWF600/180/600 | 1380 | 600 | 180 | 600 | ≤0.2 | ≤60 |

| EWF600/250/600 | 1450 | 600 | 250 | 600 | ≤0.2 | ≤60 |

| EWF800/250/300 | 1350 | 800 | 250 | 300 | ≤0.2 | ≤60 |

| EWF800/250/450 | 1500 | 800 | 250 | 450 | ≤0.2 | ≤60 |

| EWF800/250/600 | 1650 | 800 | 250 | 600 | ≤0.2 | ≤60 |